Electrolytic Tinplate (ETP) is characterized by excellent corrosion resistance, high machinability and good recyclability, it is widely used in packaging and non-packaging applications, such as food cans, paint cans, aerosol cans, etc.

We can supply electrolytic tinplate in sheet form with customer-specific length. With our automatic cut-to-length machines, we are able to cut tinplate coils into tinplate sheets of any desired length in accuracy. With our on-line pinhole detection system, unqualified sheet will surely be rejected. Therefore, customer can conduct printing and lacquering processes as soon as possible after delivery, eliminating the need for tinplate coil cutting.

| Product | Temper | Thickness | Width | Length | Weight | Inner diameter of coil |

| Tinplate sheet | T1-T5 | 0.15-0.50 | 600-1040 | 600-1200 | Max. 2 ton | -- |

| DR7-DR9 |

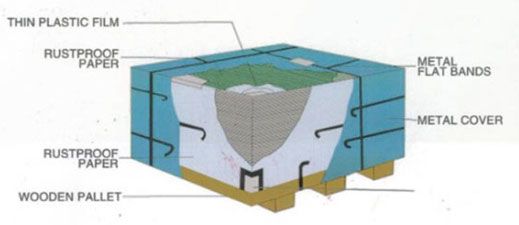

We offer choices of tinplate sheet packaging methods depending on product dimensions and specific requirements of individual customers, i.e. anti-corrosion paper + thin plastic film + metal cover + metal flat bands and plastic cover + metal corner bracket + metal strapping band + wooden pallet, which are reliable for long-time sea freight shipping.

With our standing inventory of 3000-10000mt, we can deliver tinplate sheet on short timelines.

With our standing inventory of 3000-10000mt, we can deliver tinplate sheet on short timelines. All products are carefully packed and stored before shipment.

All products are carefully packed and stored before shipment.Please provide your following information when you are placing an order or consulting, so we can better address your needs:

If you are struggling to identify your required information, please email us or give us a call, our experts will answer your questions and recommend appropriate products.

Apart from our ability in the manufacture and supply of cutting-edge tinplate coils and sheets, we can also provide one-stop services that integrate variety of tinplate processing including lacquering, printing, laminating and slitting to satisfy customers' production needs.

Read MoreElectrolytic Tinplate (ETP) is characterized by excellent corrosion resistance, high machinability and good recyclability, it is widely used in packaging and non-packaging applications, such as food cans, paint cans, aerosol cans, etc.