Request a quote now

We will deliver immediate feedback and pricing precisely oriented to your requirements

Jiangsu Global Packing Technology was founded over 15 years ago. Today, we have grown into a reliable global supplier of electrolytic tinplate (ETP). With our in-depth expertise and complete manufacturing equipment we are able to supply tinplate coils and tinplate sheets that meet both international standards and customers' individual requirements.

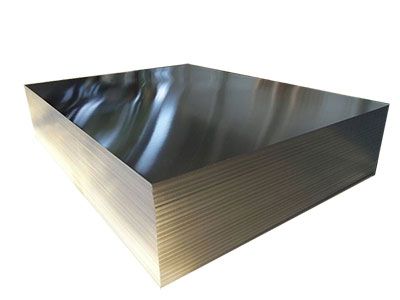

Electrolytic Tinplate (ETP) is a thin steel sheet coated with tin. It is a recyclable material for a huge variety of packaging applications such as food cans, paint cans, chemical pails, lubricant cans, aerosol cans, sanitary cans, easy open ends, tabstocks, crown corks and twist off closures (lug caps), as well as non-packaging applications including oil filter shells, bakeware pans, etc.

Electrolytic Tinplate (ETP) is widely used in packaging and non-packaging applications, such as:

| Type of Coating | Designation of Coating Weight | Nominal Coating Weight | Minimum Ave. Coating Weight | |||

| JIS | ASTM | g/㎡ | 1b/BB | g/㎡ | 1b/BB | |

| Specification | 1.1/1.1 | #10 | 2.2(1.1/1.1) | 0.1 | 1.8(0.9/0.9) | 0.08 |

| 2.8/2.8 | #25 | 5.6(2.8/2.8) | 0.25 | 4.9(2.45/2.45) | 0.22 | |

| 5.6/5.6 | #50 | 11.2(5.6/5.6) | 0.5 | 10.5(5.05/5.05) | 0.47 | |

| Differentially Coating | 1.1/2.8 | #10/25 | 1.1/2.8 | 0.10/0.25 | 0.9/2.45 | 0.08/0.11 |

| 2.8/5.6 | #25/50 | 2.8/5.6 | 0.125/0.25 | 2.25/5.05 | 0.11/0..23 | |

| Code | Chinese Standard | Japanese Standard | American Standard | European Standard | International Standard |

| GB/T 2520 | JIS G3303 | ASTM A623M | DIN EN 10203 | ISO 11949 | |

| T-1 | TH50+SE | T-1 | T-1(T49) | TS230 | TH50+SE |

| T-2 | TH52+SE | T-2 | T-2(T53) | TS245 | TH52+SE |

| T-2.5 | TH55+SE | T-2.5 | T-2.5(T55) | TS260 | TH55+SE |

| T-3 | TH57+SE | T-3 | T-3(T570) | TS275 | TH57+SE |

| T-4 | TH61+SE | T-4 | T-4(T61) | TH415 | TH61+SE |

| T-5 | TH65+SE | T-5 | T-5(T65) | TH435 | TH65+SE |

| DR7 | H71+SE | DR7 | DR7(T71) | TH520 | H73+SE |

| DR8 | H73+SE | DR8 | DR8(T73) | TH550 | H73+SE |

| DR9 | H76+SE | DR9 | DR9(T76) | TH620 | H76+SE |

Read More

Read More

Our tinplate coil is available in a weight range of 3-8 tons.

After receiving the cargo, customer can flexibly cut the tinplate coil into different sizes sheets, or slit it into narrower strips.

Read More

Read More

We can supply electrolytic tinplate in sheet form with customer-specific length. With our automatic cut-to-length machines, we are able to cut tinplate coils into tinplate sheets of any desired length in accuracy.

Jiangsu Global Packing Technology as a trustworthy manufacturer and supplier of electrolytic tinplate (ETP) in China can provide customers all over the world with tinplate coils and sheets, as well as tinplate processing services including lacquering, printing, laminating and slitting to satisfy customers' production needs. At our manufacturing plant, tinplate coils and sheets are manufactured through our advanced process of cold rolling, batch annealing and tin coating to ensure that they are in compliance with the JIS Standard.

We will deliver immediate feedback and pricing precisely oriented to your requirements

Electrolytic Tinplate (ETP) is characterized by excellent corrosion resistance, high machinability and good recyclability, it is widely used in packaging and non-packaging applications, such as food cans, paint cans, aerosol cans, etc.